Packaging and Merchandising | Exercises

Week 1 - Week 7

Wynne Pankusya

0333258

Packaging and Merchandising

Exercises

Lecture Notes

Week 1

First day of the class, Mr.Shamsul let us know what we are the things that we will do in this module and also to create a group for the first exercise. The first thing we have to do is to actually find what is the purpose of packaging. Mr. Shamsul let us have about 30 minutes to search and understand more about functionality of packaging and put it in Padlet along with other students as well.

Based on my understanding, this is the answer I wrote for the question :

The main purpose of the packaging is to make sure it delivers the goal of the product and efficiently used and attracting the consumers. Packaging should have primary functions (safety & storage functions), secondary functions (brand visibility and marketing), and additional function (sustainability). These functions of the packaging supposed to let the consumer trust your product / brand.

Primary Functions

Protective function : To protect the content inside the product from loss, damage and theft from the environment. It required protection from climate condition, contamination and other negative impact.

Storage function : Packaging materials & containers required for producing packages must be stored in many different locations before packaging of the goods and once the package contents have been used. Packaging must fulfil a storage function

Loading and transport function:Packaging should be designed to be easily handled and to permit space-saving storage. Shape & strength of packages should be safe and efficient to be held, lifted, moved, set down and stowed.

Secondary Functions

Sales function : To enable or promote the sales process efficiently by the packaging

Promotional function : To attract potential purchaser’s attention and to have positive impact upon the purchasing decision.

Service function : To show the informations on the packaging based on the contents of the product and the usage of it.

Guarantee function : The packaging should have undamaged and unblemished package with the guarantee of their nature, composition, weight, quantity, and storage life. This is for consumer protection and product liability.

Tertiary Functions

Week 2

Monday 10/04/2019

Because of the unsuccessful trial of previous box design, I tried another way and this time I also changed my product into a fragile glass bottle. Therefore I changed some of the measurement and also the shape of the packaging. Because it is a fragile glass, I used a packaging that have handle on it so it would be easier to carry it anywhere.

Because it will be submitted and finalised, I used laser cut for cutting the die line.

Promotional function : To attract potential purchaser’s attention and to have positive impact upon the purchasing decision.

Service function : To show the informations on the packaging based on the contents of the product and the usage of it.

Guarantee function : The packaging should have undamaged and unblemished package with the guarantee of their nature, composition, weight, quantity, and storage life. This is for consumer protection and product liability.

Tertiary Functions

Additional Function : Whether the materials / containers may be reused once the package content have been used such as recycling.

On this class, Mr.Shamsul let us write down what are the things that we need to consider in creating the packaging. The considerations are pretty much leads to the purposes and functions of packaging.

Purchase intention is the likelihood of a customer buying the same product again based on their purchase history.

Purchase decision is the thought process that leads a consumer from identifying a need, generating options, and choosing a specific product and brand.

Where it begins

A good design should always reflect the product and the creativity and personality of the company. From the shape of the package to the materials used should not forget its functionality. For example, of the many things to take into consideration when creating a package, one of the most important things to remember is certainly the protection it offers to the product. There's no point in making a package look visually interesting if it is not protecting the product.

How to make the Perfect Packaging Design

Even though by following the trend in packaging designs, does not mean it would work for the product. Don't let your customer doesn't recognise your product just because you want to follow the trend and lose the brand identity. People want to get the information in quick and simple way more than anything. Companies want people to buy their products, they don't want people to walk away and buy a competing product merely because the information can be accessed more quickly on their package.

What customer wants

Good packaging should also reflect the personality of the company. Logo plays a vital part when it comes to marketing. Customers want to associate a product with something positive and the packaging design is often the first thing that comes to their mind.

Role of Packaging

A. Function

The true function of product packaging is to protect the product during shipment from the manufacturer to the store selling it. Packaging is also a form of protection as the product sits on store shelves waiting for consumers to come along and purchase it. In marketing and market development, packaging is the "dress" on the product, which can play a role in whether the product sells in a new market or to new customers.

B. Branding

Product packaging also plays a vital role in the branding process of the product. InvestorWords defines a brand as a symbol, wording or another type of mark that differentiates a product or business from its competition, and branding is an essential part of marketing for many products and companies. Some products carry different branding, depending on the market in which they are sold especially in different countries.

C. Benefits

Packaging help sell the product because it provides space for sharing information about the product. For example, some packaging contains marketing messaging on the front to attract customers to pick it up and look at the product. In essence, the packaging can help to paint a picture of how the product benefits the customer.

D. Features

Packaging also can share information on the features of the product. Size, measurements, uses and more printed on the packaging of a product can help customers decide if the product fits their needs. For example, if a customer is shopping for an under-the-sink garbage can, he needs to know the measurements of a product to make sure it will fit under his sink.

E. Identification

Packaging also can help customers identify the products or companies they are loyal to. For example, if a local restaurant decides it wants to sell its famous salad dressing in retail stores, the salad dressing packaging and label may carry the restaurant's logo, name, and colour scheme. Using packaging that carries the same brand helps customers of the restaurant identify the brand when shopping at the local grocery store.

What is on a packaging ?

A. Clarity and Simplicity

Next time you go to a supermarket, pick a random shelf and browse through some products. Glance at each and ask yourself two very simple questions: What's this product for? What's the brand behind it?

B. Honesty

By depicting a product ten times better than it actually is, you're misleading and ultimately disappointing the consumer, which only leads to poor sales performance and very bad brand image. It is the task for designer to represent the best way possible but keep in mind that consumers deserve to be treated right.

C. Authenticity

Originality, Character and Memorability are at the heart of great brands and of course, great packaging designs. It's easy to understand why there are hundreds of products out there, all competing for consumers' attention. The only way to set your brand apart is to be different, to be authentic.

D. Extensibility

A product packaging design concept should allow for an easy introduction of a new line extension (product variation) or a sub-brand. Always design product packaging with the future in mind. This means creating a visually systematic design which allows for easy changes of product visual or other information, so you get a fine looking family of products in the end.

E. Practicality

Practicality deals with the actual shape, size and functionality of the product container, not just the label or wrap. The more practical the product, the more sales it gets.

Flip Classroom

Instructions

Exercises

Exercise 1 : Die-line Exercise

Week 1

Wednesday 03/04/2019

First of all, we have to find an item that is not smaller than 15cm and not bigger than 30cm to create a box with. I chose a water bottle as my first choice. We have to create a prototype out of whatever material we wanted. I started measuring the bottle and make an estimate size and die-line of the box.

After the measurement is done, I moved on to create the die-line prototype with an art card material. The bottom of the box should be able to lock (not glued). So I changed a bit when I applied it into the art card. The prototype supposed to let you know what are the errors before you actually do it with laser cut.

Wednesday 03/04/2019

On this class, Mr.Shamsul let us write down what are the things that we need to consider in creating the packaging. The considerations are pretty much leads to the purposes and functions of packaging.

Week 2

Monday 08/04/2019

Importance of Packaging Design

In the process of branding a product, everything does not stop with the logo. Humans are visual creature which is why customers are drawn to products that look good key part of associating brand to a certain thing. Customers that are drawn to a package are bound to remember it later. Key part of marketing product and ensuring it sells is the packaging design.

Purchase intention is the likelihood of a customer buying the same product again based on their purchase history.

Purchase decision is the thought process that leads a consumer from identifying a need, generating options, and choosing a specific product and brand.

Where it begins

A good design should always reflect the product and the creativity and personality of the company. From the shape of the package to the materials used should not forget its functionality. For example, of the many things to take into consideration when creating a package, one of the most important things to remember is certainly the protection it offers to the product. There's no point in making a package look visually interesting if it is not protecting the product.

How to make the Perfect Packaging Design

Even though by following the trend in packaging designs, does not mean it would work for the product. Don't let your customer doesn't recognise your product just because you want to follow the trend and lose the brand identity. People want to get the information in quick and simple way more than anything. Companies want people to buy their products, they don't want people to walk away and buy a competing product merely because the information can be accessed more quickly on their package.

What customer wants

Good packaging should also reflect the personality of the company. Logo plays a vital part when it comes to marketing. Customers want to associate a product with something positive and the packaging design is often the first thing that comes to their mind.

Role of Packaging

A. Function

The true function of product packaging is to protect the product during shipment from the manufacturer to the store selling it. Packaging is also a form of protection as the product sits on store shelves waiting for consumers to come along and purchase it. In marketing and market development, packaging is the "dress" on the product, which can play a role in whether the product sells in a new market or to new customers.

B. Branding

Product packaging also plays a vital role in the branding process of the product. InvestorWords defines a brand as a symbol, wording or another type of mark that differentiates a product or business from its competition, and branding is an essential part of marketing for many products and companies. Some products carry different branding, depending on the market in which they are sold especially in different countries.

C. Benefits

Packaging help sell the product because it provides space for sharing information about the product. For example, some packaging contains marketing messaging on the front to attract customers to pick it up and look at the product. In essence, the packaging can help to paint a picture of how the product benefits the customer.

D. Features

Packaging also can share information on the features of the product. Size, measurements, uses and more printed on the packaging of a product can help customers decide if the product fits their needs. For example, if a customer is shopping for an under-the-sink garbage can, he needs to know the measurements of a product to make sure it will fit under his sink.

E. Identification

Packaging also can help customers identify the products or companies they are loyal to. For example, if a local restaurant decides it wants to sell its famous salad dressing in retail stores, the salad dressing packaging and label may carry the restaurant's logo, name, and colour scheme. Using packaging that carries the same brand helps customers of the restaurant identify the brand when shopping at the local grocery store.

What is on a packaging ?

A. Clarity and Simplicity

Next time you go to a supermarket, pick a random shelf and browse through some products. Glance at each and ask yourself two very simple questions: What's this product for? What's the brand behind it?

B. Honesty

By depicting a product ten times better than it actually is, you're misleading and ultimately disappointing the consumer, which only leads to poor sales performance and very bad brand image. It is the task for designer to represent the best way possible but keep in mind that consumers deserve to be treated right.

C. Authenticity

Originality, Character and Memorability are at the heart of great brands and of course, great packaging designs. It's easy to understand why there are hundreds of products out there, all competing for consumers' attention. The only way to set your brand apart is to be different, to be authentic.

D. Extensibility

A product packaging design concept should allow for an easy introduction of a new line extension (product variation) or a sub-brand. Always design product packaging with the future in mind. This means creating a visually systematic design which allows for easy changes of product visual or other information, so you get a fine looking family of products in the end.

E. Practicality

Practicality deals with the actual shape, size and functionality of the product container, not just the label or wrap. The more practical the product, the more sales it gets.

Week 3

Monday 15/04/2019

In this lecture we were studying about boxes type and boxes styles. In the world of packaging, there are a lot of people confused about all the different types of boxed and the interchangeable terms used to describe them.

Common Types of Boxes

Folding Cartons - Folding carton (paperboard cartons, or paperboard boxes) are some of the most common types of boxes. Eg : Cereal box

Rigid Boxes - Rigid boxes (set-up boxes) are sturdier and do not fold or collapse as folding cartons do. Usually used for high-valued item and when the product within is heavy and in need of extra support.

Corrugated Boxes - Also called corrugated board, corrugated fibreboard or combined board. Commonly refer as brown cardboard boxes. Typically has three layers with a wavy / fluted layer sandwiched between two outer flat layers. The fluted layer is where the strength of this paper product lies. Corrugated boxes are often referred as "shipper boxes" or "master packs". Mostly used to ship a company's retail-ready products. Corrugates is also commonly used as a primary retail packaging the same way a folding carton is used. Corrugated fibre is also commonly used in floor POP displays.

Common Elements in Folded Cartons

There are many variety of different box styles for folding cartons or paperboard boxes. Not just for style but in dimensions as well. Most common box styles are tuck top.

Type of tuck top boxes :

1. Reverse Tuck End (RTE)

2. Straight Tuck End (STE)

These boxes are made of art card ranging from 190 gsm (light product) to 360 gsm (heavy product).

Reverse Tuck End (RTE)

The top closure tucks from the rear to the front, and the bottom closure tucks from the front to the rear.

Pros :

1. Cost effective because you can run more boxes at one time on the sae sized paperboard as opposed to the Straight Tuck End

2. Easy assembly

3. Compact storing (stores flat) for excess packaging inventory

4. Relatively quick to load the product in this packaging

5. Works well for lighter weight products

Cons :

1. Not good for heavy products

2. Not as aesthetically pleasing because of the visible raw edges in the front of the box

Industries that most commonly use RTE :

1. Health and beauty

2. Cosmetics

3. Pharmaceutical

4. Electronics

5. Nutraceutical

Straight Tuck End (STE)

Both of top and bottom closures tuck from the front to the rear.

Pros :

1. More luxurious than RTE because there are no white raw edges visible on the front of the box

2. Avoids any impedance between the tuck flap and any front window film (see-through window to display the product)

3. Easily assembly

4. Compact storing (stores flat) for excess packaging inventory

5. Works well for lighter weight products

6. Relatively quick to load a product in this packaging

Cons :

1. More expensive, manufacturers less boxes at one time per paperboard sheet

2. Not good for heavy products

Industries that most commonly use RTE :

1. Health and beauty

2. Cosmetics

Tuck Top Snap-Lock Bottom

This box, also known as a "1-2-3 bottom", has a bottom closure that closes in 3 simple steps.

Pros :

1. Works well for heavier products (bottom closure can handle more weight)

2. Relatively quick loading (the 3 steps are easy)

3. Compact storing (stores flat) for excess packaging inventory

4. Easy assembly

5. Sits well on retail shelves because package bottom is nice and flat

Cons :

1. More expensive than a bottom tuck box

2. Takes slightly more time to "set-up"

Industries that most commonly use TTSLB :

1. Health and beauty

2. Toys

3. Food

4. Pharmaceutical

Tuck Top Auto Bottom

This box has a bottom closure that makes setting up the box a breeze

Pros :

1. Works well for heavier products (bottom closure can handle more weight)

2. Ultra fast assembly

3. Super speedy loading

4. Compact storing (stores flat) for excess packaging inventory

5. Sits well on retail shelves because package bottom is nice and flat

Cons :

1. More expensive than a bottom tuck or snap-lock bottom (factory has to perform an extra step by gluing the bottom)

Industries that most commonly use TTAB :

1. Health and beauty

2. Cosmetics

3. Toys

4. Food

5. Pharmaceutical

Closure types for the tuck top box styles

All of these Tuck Top Boxes can include "Slit-Lock" or "Friction Fit" lock features for extra snug hold and to prevent the top from bowing. The choice of box styles for folding cartons can be vast. Many of the elements listed are applicable to most of the typical box styles in common usage in current retail marketplace.

Flip Classroom

Week 2

Week 3

Week 4

BOX MAKING/DIE LINE EXERCISE – 10% (Week 2 - 3)

Construct box design dieline using Adobe Illustrator or Adobe InDesign. Choose any product as reference for the box design (minimum size of product cannot be less than 15cm either width or height). Analyze the product dimension and sketch the idea of the box dieline. You will cut the dieline using laser cut machine to construct the box. Bring along a product and your choice of MATERIAL (paper, cardboard, acrylic, etc.) for the exercise.

THERMAL FORMING – 10% (Week 5 - 7)

Thermal forming is one of many techniques that can be used as package design. Its purpose is to hold, protect and to display any product. Bring along few A3 transparency sheet and small items with no sharp end (small toys, padlock, etc.) for the exercise.

Exercises

Exercise 1 : Die-line Exercise

Week 1

Wednesday 03/04/2019

First of all, we have to find an item that is not smaller than 15cm and not bigger than 30cm to create a box with. I chose a water bottle as my first choice. We have to create a prototype out of whatever material we wanted. I started measuring the bottle and make an estimate size and die-line of the box.

|

| Fig 1.1 The bottle I used for the die-line exercise |

|

| Fig 1.2 The box template and measurement of the bottle |

After the measurement is done, I moved on to create the die-line prototype with an art card material. The bottom of the box should be able to lock (not glued). So I changed a bit when I applied it into the art card. The prototype supposed to let you know what are the errors before you actually do it with laser cut.

|

| Fig 1.3 Back side of the box |

|

| Fig 1.4 Front side of the box |

|

| Fig 1.5 The item inside the box. It fits well and the box is not too big from the actual size and also I cut the window to show the Gatorade logo |

|

| Fig 1.6 The side window of the box, to show more details |

|

| Fig 1.7 A bit of error of the top tuck flap because it is too short |

|

| Fig 1.8 The lock on the bottom is also too short so they don't meet and lock. |

Monday 10/04/2019

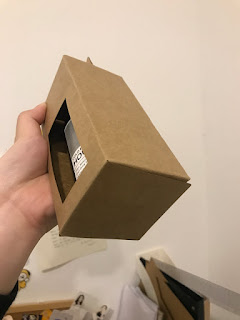

Because of the unsuccessful trial of previous box design, I tried another way and this time I also changed my product into a fragile glass bottle. Therefore I changed some of the measurement and also the shape of the packaging. Because it is a fragile glass, I used a packaging that have handle on it so it would be easier to carry it anywhere.

|

| Fig 1.9 The sketch of the measurement |

|

| Fig 1.10 Photo of the final product |

|

| Fig 1.11 Photo of the final product |

|

| Fig 1.12 Photo of the final product |

|

| Fig 1.13 Photo of the final product |

Exercise 2 : Box Design (Color Exercise)

In the class, after a group presented their presentation about colours in packaging design, Mr.Shamsul asked us to design a package that can hold a special gift that we can choose. We need to create it as a brand where we make the word mark, typography, art direction, and considerations on the packaging based one what product we chose.

|

| Fig 2.1 The Packaging design and explanations of each part |

Exercise 3 : Thermoforming Exercise

In this class, we have to make our own plastic packaging using thermoforming technique. The thermoforming process will make the hard plastic sheet formed into the desired shape based on the object we chose. The things that we had to prepare are A3 plastic sheet, and rounded objects.

However, since my plastic sheet is too thick it was hard for me to fold it and i doesn't turns out neat even when i already did straightened it with hair straightener.

|

| Fig 3.1 The process of thermoforming is to put the object first on the machine and heat the plastic to form. |

|

| Fig 3.2 After the it is vacuumed from below, we still need to heat it up until it is hardened and formed just like our objects |

|

| Fig 3.3 Result of thermoforming |

|

| Fig 3.4 Result of thermoforming with the objects |

|

| Fig 3.5 Result of Thermoforming |

|

| Fig 3.6 Result of thermoforming |

Reflections

Experience

I am quite excited about this module since it is the time I will learn more about how to create a packaging since I struggled a lot during previous branding classes to create one because I did not really understand about it.

Observation

Different kinds of items/products have different packaging materials and also different purposes. I observed that there are so much considerations to put before you actually create a packaging.

Findings

It doesn't matter when your packaging looks good but it can't hold the object or doesn't function well. We need to understand the user experience and how they will use the object to put as a consideration for creating a packaging design.

Thanks for sharning informative aritcal.Showing off the product most amazingly and uniquely is the most effective tactic used by markets and retailers to boost up their sales. However, distinctive packaging is the top-notch concern of every manufacturer. More informatin click here.

ReplyDeleteCustomization allows you to be inventive with your Custom Packaging Boxes by permitting you to look over the material to the keep going structure component on your containers

ReplyDeleteHowever, distinctive packaging is the top-notch concern of every manufacturer.Customization allows you to be inventive with your Custom Packaging Boxes by permitting you to look over the material to the keep going structure component on your containers.

ReplyDeleteAs you know, the demand for a bath bomb boxes is very high. You can target the psyche of the customers by presenting your alluring bath bombs boxes through custom packaging. If you are making homemade, then custom boxes are the best solution to enhance your reputation.

ReplyDeleteThis comment has been removed by the author.

ReplyDeletehello, it was very amazing post.bath bomb packaging boxesPackaging boxes are really necessary for your any kind of product. If you want to pack your products in stylish way then use these bath bomb packaging boxes with customized designs, styles, colors, shapes, and stocks. We are also offering error-free designing and free shipping services all over the USA.

ReplyDeletereverse tuck box packaging is a best packaging style for your brand products. This is most widely used style in the industry.

ReplyDeleteThankx for sharing this article. Its really informative article. I really enjoy your site I am waiting for new article.

ReplyDeleteVape Cartridge Boxes

At PackagingNinjas you will entertain by wholesale quantity packaging boxes. We make custom-style packaging boxes and receive orders in bulk. The massive quantity boxes will entertain your products in an amazing way. To get CBD bath bomb boxes wholesale contact us we feel glad to help you. They are available in different sizes, designs,s, and styles. We use well-equipped techniques for designing packaging bath bomb boxes. The suitable size packaging boxes will rebrand your products and place the products in a distinctive position.

ReplyDeleteCustom Cigarette Boxes

French Fry Boxes

CCustom Kraft Boxes

Hi! nice post. Well what can I say is that these is an interesting and very informative topic on packaging supply store

ReplyDeleteCreative Packaging Design is a best packaging style for your brand products. This is most widely used style in the industry.

ReplyDeleteThank you for sharing such good information. If you need best quality boxes then visit Custom CBD Boxes!

ReplyDelete